- 您现在的位置:买卖IC网 > Sheet目录1181 > 82542350 (Wurth Electronics Inc)VARISTOR 45VDC 1200A 2220

�� �

�

�

�Spezifikation� für� Freigabe� /� specification� for� release�

�Kunde� /� customer� :�

�Artikelnummer� /� part� number� :�

�Bezeichnung� :�

�82.542.350�

�description� :�

�HIGH� SURGE� 2220� SMD� VARISTOR�

�SMD� size:�

�2220�

�C� L?tpad� /� soldering� spec.� :�

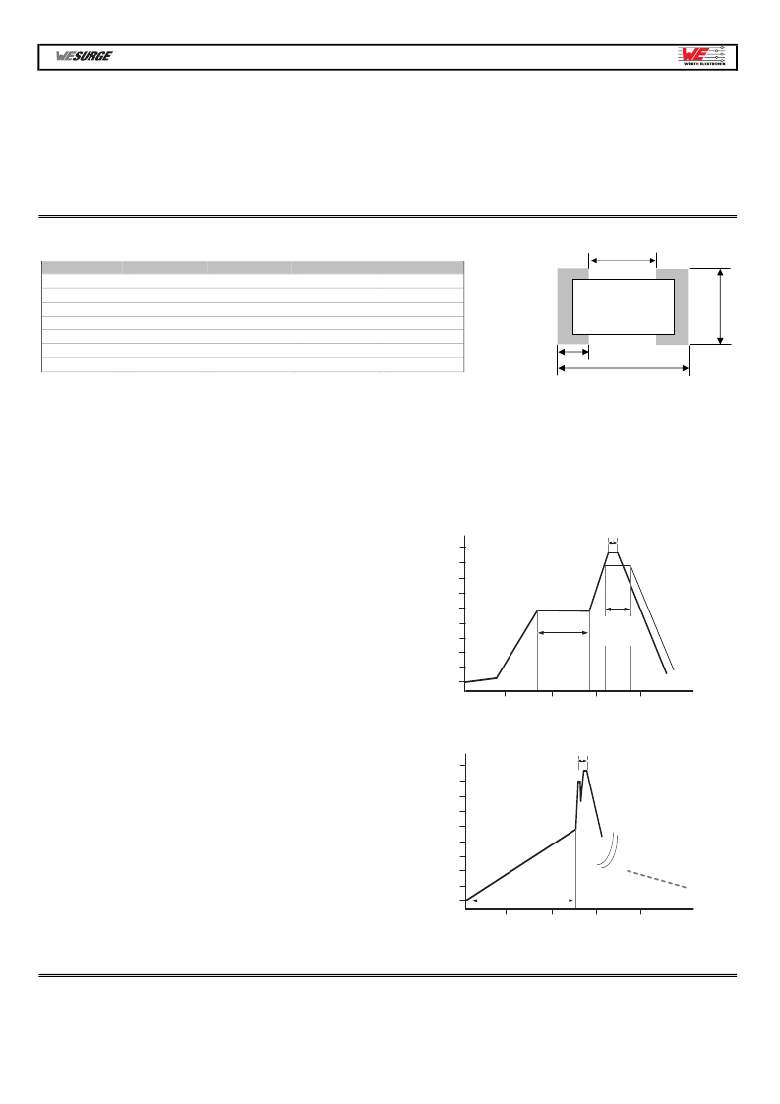

�RECOMMENDED� SOLDER� PAD� LAYOUT�

�(Unit� :� mm)�

�A�

�SISE�

�0402�

�0603�

�A�

�0.4~0.6�

�0.8~1.2�

�B�

�1.0~1.8�

�1.7~3.0�

�C�

�0.6~0.7�

�1.2~1.6�

�D�

�0.6~1.2�

�0.9~1.8�

�0805�

�1206�

�1210�

�1812�

�2220�

�1.0~1.5�

�1.8~2.5�

�1.8~2.5�

�2.5~3.5�

�3.5~4.6�

�2.1~3.8�

�3.0~5.8�

�3.2~6.1�

�4.0~7.3�

�5.0~8.5�

�1.5~2.1�

�1.8~2.6�

�2.8~3.8�

�3.3~4.5�

�5.2~6.2�

�1.1~2.3�

�1.2~3.3�

�1.3~3.5�

�1.5~3.8�

�1.5~3.9�

�D�

�C�

�B�

�1� -� The� solder� paste� shall� be� printed� in� a� thickness� of� 150� to� 200� μ� m.�

�2� -� The� SIR� test� of� the� solder� paste� shall� be� done� (� Based� on� JIS-Z-3284� )�

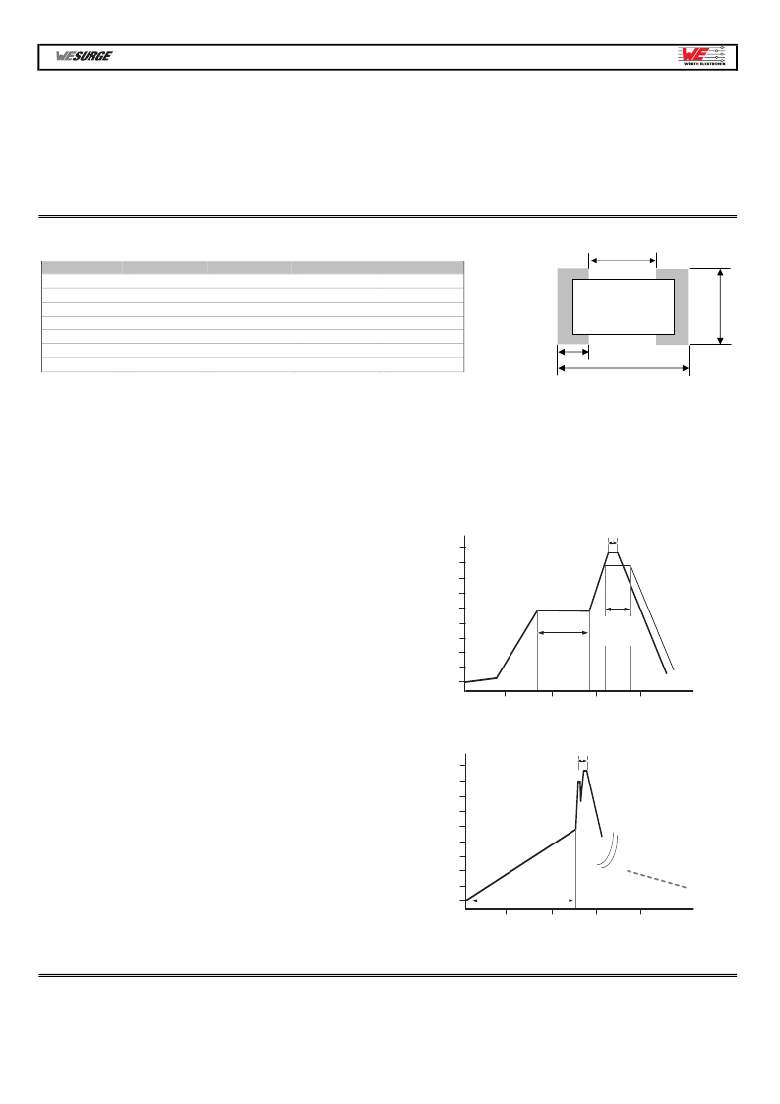

�3� -� IR� reflow� Pb� Free� Process� suggestin� profile� (Based� on� J-STD-020-C):�

�Rapid� heating,� partial� heating� or� rapid� cooling� will� easily� cause� defect� of� the� component.� So� preheating� and� gradual� cooling� process� is�

�suggested.� IR� soldering� has� the� highest� yields� due� to� controlled� heating� rates� and� solder� liquidus� times.� Make� sure� that� the� element� is� not�

�subjected� to� a� thermal� gradient� steeper� than� 3� degrees� per� second.� 2� degrees� per� second� is� the� ideal� gradient.� During� the� soldering� process,�

�pre-� heating� to� within� 175� degrees� of� the� solders� peak� temperature� is� essential� to� minimize� thermal� shock.�

�4� -� Soldering� recommend� paste� is� Sn� 96.5/Ag� 3.5�

�Peak� Temp.�

�-� Preheat�

�1.The� temperature� rising� speed� is� suggested� to� be� 2~3°C/s.�

�2.Appropriate� preheat� time� will� be� from� 60� to� 120� seconds.�

�3.Temp.� maintain� at� 175� +/-25°C� 120� seconds.�

�-� Heating�

�1.Careful� about� sudden� rise� in� temperature� as� it� may� worsen�

�the� solder� ability.�

�275�

�250�

�225�

�200�

�175�

�150�

�260°C�

�(3� to� 10sec)�

�Peak� Temp.�

�245°C�

�2.Set� the� peak� temperature� in� 235°C� 10-20s� or� 260°C� 3-10s.�

�-� Cooling�

�1.Ramp� down� rate� 6°C/s� max.�

�125�

�100�

�75�

�Peak� Temp.�

�175°C�

�(60� to� 120sec)�

�(10� to� 20sec)�

�25�

�※� Perform� adequate� test� in� advance� as� the� reflow� temperature�

�profile� will� vary� according� to� the� conditions� of� the� manufacturing�

�process,� and� the� specification� of� the� reflow� furnace�

�01:00:00�

�02:00:00�

�03:00:00�

�Time� (mn)�

�04:00:00�

�4� -� Wave� Soldering� Process�

�Peak� Temp.�

�Ramp-up� rate� 3°C/s� max.�

�Temp.� maintain� at� 175� +/-25°C� 180� seconds� max.�

�Peak� temperature� 260°C� 3-10s.�

�Ramp� down� rate� 6°C/s� max.�

�to� thermal� shock,� a� preheat� is� recommended� in� the� soldering�

�process.� and� the� peak� temperature� should� be� under� controlled�

�rigidly� in� the� solder� process.�

�5� -� Hand� Soldering� Process�

�Preheating� 150°C�

�Temperature� of� soldering� iron� tip� 380°C� max.� 3� to� 5� sec�

�275�

�250�

�225�

�200�

�175�

�150�

�125�

�100�

�75�

�25�

�260°C�

�(3� to� 10sec)�

�Preheat.�

�175°C� 150sec� max.�

�The� Varistorrs� shall� be� cooled� gradually� at� room� ambient� temperature�

�01:00:00�

�02:00:00�

�03:00:00�

�04:00:00�

�Time� (mn)�

�6� -� Ultrasonic� cleaning�

�For� preventing� failures� or� damages.� Frequency� 29MHz� max� -� radied� Power� 20W/l� max� -� Period� 5mn� max�

�Würth� Elektronik� eiSos� GmbH� &� Co.KG� -� Radialex� department�

�D-74638� Waldenburg� ·� Max-Eyth-Stra?e� 1� -� 3� ·� Germany� ·� Telefon� (+49)� (0)� 7942� -� 945� -� 0� ·� Telefax� (+49)� (0)� 7942� -� 945� -� 400�

�http://www.we-online.com�

�PAGE/SEITE� 2� -� TO/VON� 5�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

82550040

VARISTOR 5.5VDC 80A 0805

82550060

VARISTOR 9.0VDC 80A 0805

82550110

VARISTOR 14VDC 100A 0805

82550140

VARISTOR 18VDC 100A 0805

82550200

VARISTOR 26VDC 100A 0805

82550250

VARISTOR 30VDC 100A 0805

82551140

VARISTOR 18VDC 100A 1206

82551200

VARISTOR 26VDC 100A 1206

相关代理商/技术参数

825426-1

制造商:TE Connectivity 功能描述:STRAIN RELIEF CLAMP - Bulk

825-4-3/4

制造商:Greenlee Textron Inc 功能描述:HOLESAW VARIABLE PITCH

825-4-3/8

制造商:Greenlee Textron Inc 功能描述:HOLESAW VARIABLE PITCH

82543-00000

功能描述:3M CLEAR POLYCARBONATE FACES 制造商:3m 系列:* 零件状态:在售 标准包装:1

82-54-3053

制造商:MOLEX 功能描述:NOTCHED CABLE MVI-SARCO

82-54-3054

制造商:MOLEX 功能描述:

82543140

功能描述:压敏电阻 2380pF, 0.5W 18vdc RoHS:否 制造商:EPCOS 产品:MLV 电压额定值 DC:22 V 电压额定值 AC:17 V 钳位电压:50 V 直径: 峰值浪涌电流:30 A 浪涌能量额定值:75 mJ 电容:74.2 pF 工作温度范围:- 55 C to + 125 C 安装:SMD/SMT 封装:Reel

82-54-3165

制造商:MOLEX 功能描述: